Know-how and expertise

DARI works hard everyday to improve the quality of its products by using its know-how and unique expertise in the couscous and pasta sector. This know-how is the result of many years of experience in this field and a culture of excellence at all levels of the company.

With a very high quality standard, DARI has organised itself to control its production in order to ensure optimal, constant and regular quality for its consumers.

This requirement is met by:

a) Unique selection of premium raw material : Strict selection of durum wheat semolina based on several criterias, determinants of food safety....

b) Control of the production process: Control of the raw material received, control and monitoring of the various manufacturing stages (mixing, rolling, steam cooking, drying, cooling, sieving and storage) with the help of dedicated equipment and software.

This requirement is met by:

a) Unique selection of premium raw material : Strict selection of durum wheat semolina based on several criterias, determinants of food safety....

b) Control of the production process: Control of the raw material received, control and monitoring of the various manufacturing stages (mixing, rolling, steam cooking, drying, cooling, sieving and storage) with the help of dedicated equipment and software.

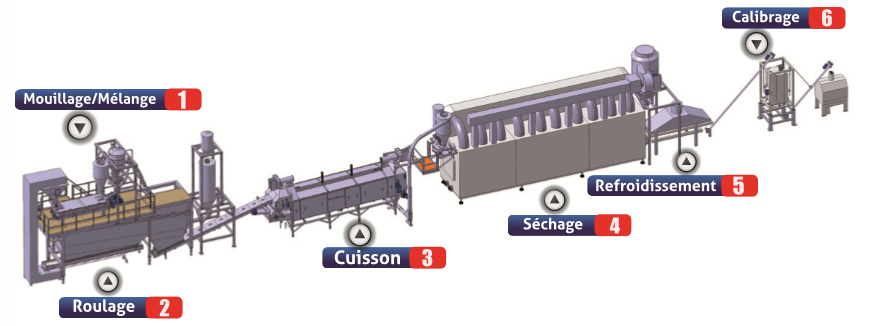

How couscous is produced ?

- Semolina is moistened with water.

- Wet semolina goes in giant rotating drums that allow the formation of grain by agglomeration.

- Formed grains cook in large steamer through a stainless steel conveyor.

- After the steam cooking step, the grains of couscous are dried to allow their conservation.

- Couscous is then cooled after drying to bring moisture rate to the required level.

- Calibration is the step that separates the grains of different sizes (medium / fine / other)

- Couscous is then conducted to silos of storage before their packaging.